Core Materials

Composite core materials are designed to provide thickness to a laminate, this in turn increases the stiffness keeping weight to a minimum. Core materials are used in a wide range of industries including Marine (boat hulls), leisure and automotive. The Core is sandwiched between layers of reinforcement thus sealing it in, equal laminate specification either side of the Core is advised for maximum benefits

Please note that full 1.2m x 2.4m sheets of these materials cannot be delivered to residential addresses, and will be cut in half. Please get in touch if you have any questions.

Click here for a guide to the various composites core materials

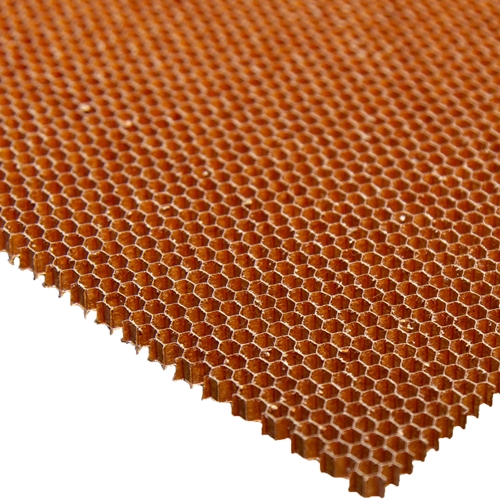

In the world of composite material construction, core materials are integral to achieving a balance between strength and weight efficiency. These materials are not only pivotal in the marine sector but also in aerospace, automotive, and sporting goods industries. Core materials such as foam, balsa, and honeycomb structures offer unique properties that enhance the performance of composite laminates. They add thickness to the laminate, significantly improving its stiffness without a corresponding increase in weight, a crucial factor in many high-performance applications. This technology is especially relevant in crafting lightweight yet sturdy components where weight savings are paramount, such as in racing yachts or performance vehicles.

The use of core materials in composite structures also aids in the distribution of loads and stresses, enhancing the durability and longevity of the final product. The variety of core materials available allows for tailored solutions to specific engineering requirements. For instance, foam cores provide excellent strength-to-weight ratios and are versatile for complex shapes, while balsa cores offer superior compressive strength and are often used in high-load areas. Honeycomb cores, known for their exceptional shear and compression properties, are widely used in aerospace applications. As technology advances, the development of new core materials and hybrid solutions continues to drive innovation in composite engineering, offering even greater performance benefits across various industries.